The purchase order will be raised by Purchasing Department to the vendor with the agreed price, materials/services, quantity, delivery terms, and payment terms.

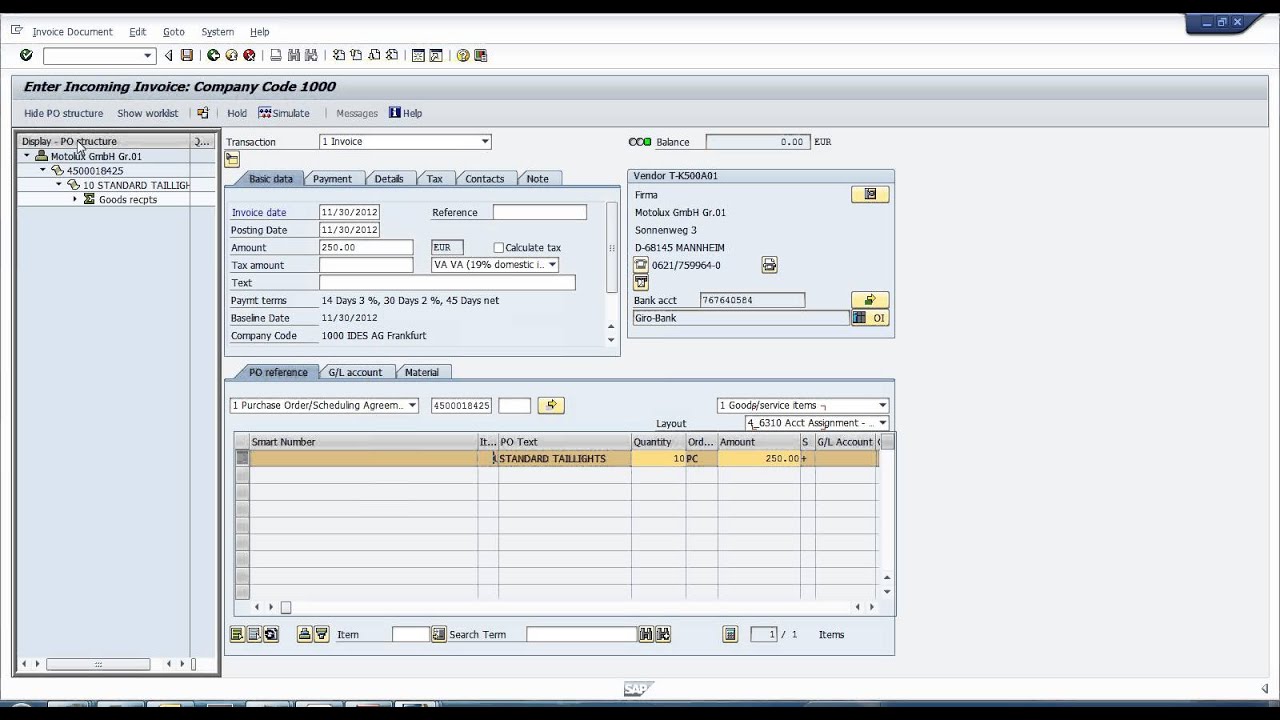

The Purchasing department will negotiate the required materials/services with the external vendors, and they will finalize the vendor. The store’s department simply enters the required material and quantity in the purchase requisition. If the stock is not available in the warehouse, then the store’s department will raise the purchase requisition to the purchasing department. If the stock is available in the warehouse, then the store’s department will send the stock to the production department. Generally, In the organization, the production department team checks with the store’s department team for the required stock/materials. Purchase Requisition is raised by the stores department to the Purchase department internally. We will understand the master data activities like a material master, purchase Info record, source list, and transaction activities like Purchase Requisition, Purchase Order, Goods Receipt, and Invoice Posting. I have explained few popular scenarios in this blog post. It deals with procuring materials, services, different contracts associated with procurement. Hence this process is popular with the word ‘P2P’ Process. The procurement process starts from purchase requisition and ends with payment to the vendor. A new info record will be created.In this document, I would like to explain the different scenarios in the procurement process. Step 4 − Provide the info record note that can be called as info record description.

Step 3 − Fill in the required details such as material group, 1st/2nd/3rd reminder, vendor material number, personal details, order unit, origin data, and sort term. In the info category, select standard or subcontracting, or pipeline or consignment, according to the requirement. Step 1 − On the SAP Menu screen, select the Create icon, by following the above path. Logistics ⇒ Material Management ⇒ Purchasing ⇒ Master Data ⇒ Info Record ⇒ Create This info record contains vendors price that is to be paid for withdrawing material from consignment stock.įollow the steps given below to create a Purchase Info Record. For Example: like water,electricity.Ĭonsignment − Consignment info record has information on material that is kept at ordering party premises. Pipeline − Pipeline info record has information on material that is provided by vendor through pipes. This info record will include price for assembling the raw material that is supplied by the ordering party. Subcontracting − Subcontracting info record has information on subcontract orders. This info record will include vendors price for supplying the particular material. Standard − Standard info record has information on standard orders (orders include details of vendor and material). Info record can be maintained for four procurement types, which are as follows − Purchase info record can be maintained at the plant level or at the purchasing organization level. For example, a vendor’s current price of a particular material is stored in info record. Purchasing info record stores information on material and vendor, supplying that material. The key points about purchase info record are as follows − The combined information of material and vendor altogether is kept in a record that we call as purchase info record. Material and vendor master are separate data records for keeping information of materials and vendors from where material is procured. SAP R/3 works on all real-time data that includes material master and vendor master.

0 kommentar(er)

0 kommentar(er)